In a circular model in the agri-food industry, manufacturers produce food, package it and then sell it to distributors. Finally, consumers have their food, in a labeled packaging.

Consumer awareness and information are essential. In fact, do you now have the reflex to consult the MDA Minimum Durability Dates for your food products? To prevent food waste, consumers are now invited to smell and taste the food in order to judge potential consumption after exceeding the registered MDA.

Sometimes, in this well-established supply chain, health scandals can occur. We have all heard about the problems of larvae in infant milk cans, or the presence of pathogens in foodstuffs, even frozen ones.

These health scandals very regularly lead to the hospitalization of unlucky consumers and can even lead to deaths. This is called food insecurity.

Food safety is ensured by frequent checks at all levels of the value chain. Whether self-checks, carried out by the actors themselves, or by a third party.

By changing the paradigm, from a linear economy to a circular economy, the health risk becomes, in theory, more present. Like any change, it is necessary to adapt the security approach and analyze this new value chain. SGS helps to ensure this security, particularly in the R3PACK project.

Reuse, this is the future of our food consumption. Packaging adapted to the uses and different foodstuffs but reused for several cycles.

Manufacturers, distributors, logisticians must work hand in hand to (re)birth this economy.

Current food safety and processes must therefore also evolve to continue to protect consumers.

Working together. Working together is the key to success for this mad project. The European Commission has therefore decided to work on the value chain through a project called R3PACK.

R3PACK includes two projects, one on substitution, and the other on reuse.

Let’s focus on reuse.

In the R3PACK reuse project, the objective is to put into practice large-scale reuse loops within several Carrefour and Système U stores on a large number of food products.

Manufacturers and distributors are working hand in hand to make this crazy project a reality.

And what about food safety? this is where SGS’s work begins, from the genesis of the project. SGS is the global leader in certification, inspection, auditing and testing worldwide. With more than 93,000 employees, our expertise is worldwide recognized.

In the French teams, we have experts in food contact, food safety and packaging.

Our first mission was to take stock of existing regulations. Indeed, to embark on research and implementation of a new system, you must be aware of the applicable regulations to fully embark on the project.

Then SGS intervened on two distinct but closely linked areas: a washing audit grid and a reuse protocol verifying the suitability for food contact of reusable packaging.

Why a washing audit grid? we were talking about reuse. Who says reuse, necessarily says washing. After consuming a dish or any other food, the container must be washed before being reused.

Washing is one of the essential steps in reuse, especially from a food safety point of view.

What is an audit grid? An audit grid is a list of points to control and verify in order to certify at the end of the evaluation the ability or not to be able to carry out an activity.

Like the assessment of the driving license, errors can be major, therefore canceling this ability, or minor, which can lead to a more in-depth points of vigilance.

To harmonize the practices of washers, SGS has therefore constructed an audit grid. This audit grid aims to verify the result, the final food safety.

Washers are therefore free to wash the containers at the temperature, humidity or even use detergents as they wish.

The audit control points are divided into 19 criteria. This includes flow management, between dirty packaging and clean packaging to avoid any contamination; microbiological checks and analyzes on clean packaging to be certain of consumer safety or even the training of employees in this profession.

Today, the audit grid was presented to the washer and is waiting for volunteer washer to test it.

Now let’s move on to packaging reuse protocol. Today there are regulations for food contact for packaging. What is food contact? food contact tests validate the safety of packaging, it means by eating a salad in a plastic bowl, we will not ingest microplastics or other molecules harmful to human body.

In the laboratory, we determine the simulants, chemical solutions substituting our foodstuffs (such as 3% acetic acid for foods with a pH < 4.5). Then at defined temperature and duration conditions, we bring the packaging and the simulant into contact. Finally, we analyze the simulant.

These tests are regulated and standardized. This means that a method has been validated among a consortium of experts who have agreed on how these tests should be carried out.

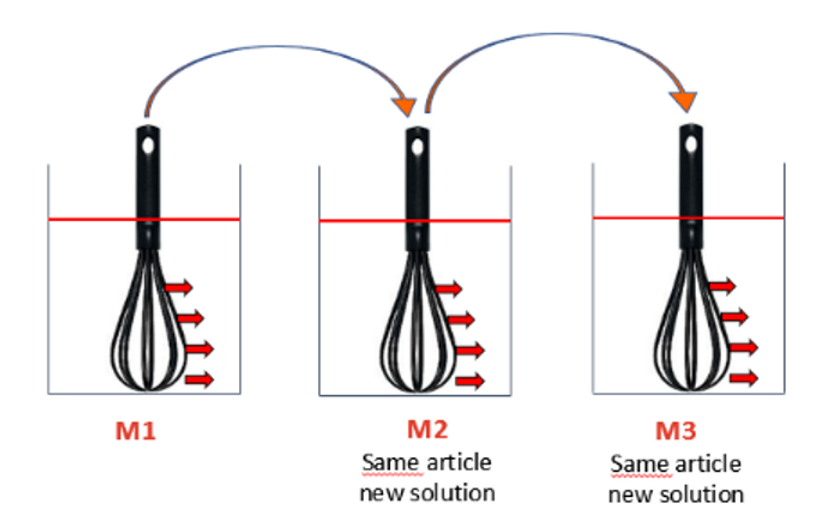

Today, the regulations applicable to food contact with repeated use, and therefore to reuse, result in a food contact test carried out three times in a row.

As you understood, this absolutely does not reflect reality.

Packaging intended for reuse is washed, microwaved and subject to abrasions linked to cutlery. Thermal shocks, falls or even transport can also damage them.

The European Commission therefore wanted SGS to create a protocol for the suitability of reusable packaging for food contact. In this case, how can we validate reusable packaging in contact with food?

The idea here is to add performance tests to food contact tests and to recreate reuse loops but in a repeatable manner so that the results can then be analyzed.

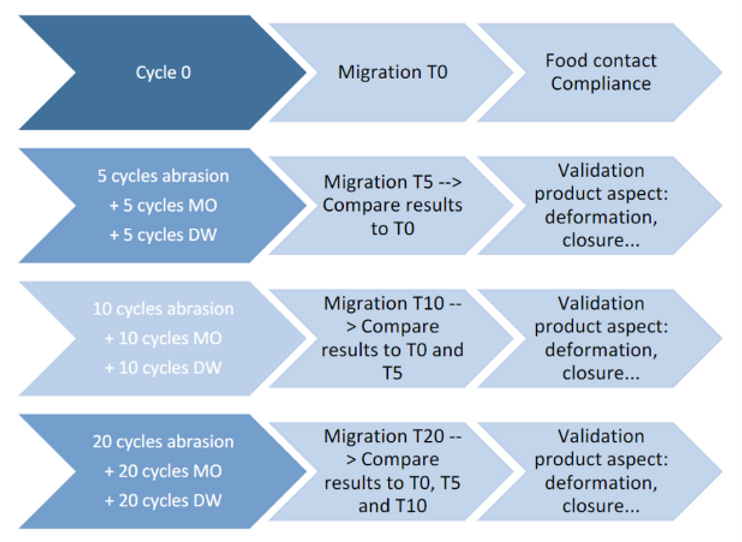

The hardest choice was choosing which performance tests were the most critical. Abrasion, to simulate cutlery blows, microwave, only for microwaveable packaging and washing were chosen.

The test methods have been carefully selected with a rigorous protocol to ensure repeatability. Repeatability is one of the pillars of testing, because without repeatability we cannot make a conclusion.

We therefore carried out cycles of these tests as shown in the protocol below.

To this protocol, we have also added a screening of chemical substances, the NIAS. NIAS are unintentionally added substances: substances used in the manufacture of plastics may contain impurities from their manufacture and may form reaction and degradation products during the production or processing of the food contact material. Present in packaging, these can be released after a certain number of aging cycles in the foods we consume.

NIAS can have genotoxic effects on humans.

A protocol but for which packaging? the R3PACK project requires a study for 20 cycles. With the (RE)SET team, we therefore benchmarked the market to find several packaging candidates for the reuse protocol. The selection was tough, because we had to select several materials and several shapes or colors of containers to represent today’s market.

The packaging chosen today for the real-life demonstration, those which will be in store, differ from the packaging tested to test the protocol. SGS will therefore have to test these new packaging to ensure perfect safety for future enlightened consumers participating in this great project.

This project has received funding from the European Union’s Horizon Europe Research and Innovation Programme under Grant Agreement No 101060806.